Air Drying Services

General Information about the PS Engineering Pipeline Air Dryer System

Why is it necessary to dry a gas pipeline?

Free water film left in hydrostatic tested pipelines can cause formation of hydrates:

Hydrocarbon gas hydrate build-up in natural gas pipelines narrows the pipe profile and can cause a considerable loss of efficiency due to the increased friction load. Narrowing of the internal pipeline diameter starts slowly, but as it changes flow and pressure conditions it accelerates to build-up hydrates. At a certain point there is a danger of the pipeline being completely plugged.

Conditions which cause formation of hydrates in natural gas pipelines exist mainly during or immediately after commissioning of new lines which have been hydrostatically tested.

This is due to residual free water or moisture remaining in the line as a film 0,1 to 0,15 mm thick, after normal dewatering with bi-directional pigs.

In existing natural gas pipelines which already are in service, free water is separated from the gas in drying- and separation plants prior to transportation.

Hydrocarbon gas hydrates belong of complex chemical compounds which are caused by free water being available in the presence of hydrocarbon gases. They are of crystalline structure and form a firm granular substance which can be compared to ice or snow.

The initial hydrate crystals thus appear on the pipe wall and in particular where there is any unevenness such as weld seams or areas of corrosion. However, crystals will also form on valves and fittings.

It is necessary, before commissioning of gas pipelines to ensure that there is no residual moisture and in particular, no free water over its complete length of the pipeline. This means that before introduction of gas, the line must be dried to prevent hydrocarbon gas hydrate to build-up.

Corrosion protection:

Another aspect is that the line should be dried immediately after bulk dewatering, to provide corrosion protection, as even with the best performance, residual water will remain in the line after dewatering, and cause corrosion.

Research has shown that by using the air-drying method of gas pipelines, which are not put into immediate operation, will protect the pipeline against corrosion. It is a known fact that corrosion is slowed considerably or even halted at dew-points below -10 ºC at atmospheric pressure.

Pipelines that have been dried by using the air-drying method after hydro-testing and have been left packed with dry air, for a period of 6 month or more showed no sign of corrosion. In cases where corrosion existed prior drying, no further spreading of corrosion could be detected.

Therefore it is also recommended that oil pipelines which are not put into immediate operation after hydrostatic test also should be dried to protect against corrosion.

How to dry a gas pipeline?

Drying methods:

Several techniques can be applied when drying a pipeline, however drying by using super dry air have been found to be the most economically compared to for example vacuum drying or drying by using methanol or nitrogen.

When a pipeline is to be dried be using super dry air, the individual test section are linked together to form one or more drying sections. Where permanent pig- launcher and receivers are not available temporary traps must be connected to the line and the drying unit is then connected to the pig launcher by flexible hoses.

Super dry air with a dew point of approximately -40ºC or lower are injected in to the pipeline and as the air passes through the section it will absorb moisture which have been left after the hydrostatic test.

Using Pigs:

During the drying operation, special foam pigs having a large absorptive capacity and high abrasion resistance are launched and propelled through the pipeline, these foam pigs distribute the residual water left in the line onto the pipe wall, thus increasing the areas of contact between residual water and air.

By using a new technology it is today possible to manufacture foam pigs which are extremely abrasion resistance. By using these long run foam pigs, drying have successfully been carried out in sections of 200 to 230 km, even in uncoated pipelines.

Therefore drying by using super dry air and long run foam pigs are also advantageously in offshore pipelines.

When a dry foam pig is received, all mainline- and bypass valves are set in half open position to dry out the valve cavities. Purging of the mainline, block valve stations and all low point drains will continue until the discharge air at all locations are below the requested dew point.

Cleaning:

As an option high density polly brush pigs can be launched as the mainline is getting dry, this combined with a high velocity of dry air will bring out dust particles from the pipeline.

| Dewpoint ºC | Moisture g/m³ air |

| +20 | >17,3 |

| +15 | >12,8 |

| +10 | >9,4 |

| +5 | >6,8 |

| 0 | >4,84 |

| -5 | >3,2 |

| -10 | >2,14 |

| -15 | >1,38 |

| -20 | >0,88 |

| -25 | >0,55 |

| -30 | >0,33 |

| -35 | >0,19 |

| -40 | >0,11 |

| -45 | >0,067 |

| -50 | >0,038 |

Unparalleled High Volume Air-Drying Technique

PS Engineering can offer an unparalleled Pipeline Air Drying system, which is revolutionary compared to any other know drying techniques. The system is used for drying of large diameter and long section pipelines, piping- and production systems and LNG Tanks.

Drying Unit:

| Volume: | 4000 m3/h (2.350 cfm) at sea level. |

| Dew point: | -15 to -40 °C. (-15°C @ 4.000 m3/h. -25 °C @ 2.500 m3/h. -40 °C @ 1500 m3/h.) |

| Discharge air: | 100% oil free. |

| Fuel consumption: | 25 to 40 Litres pr hour. |

| Max. Discharge Pressure: | 0,6 bar. at 4.000 m3/h + 1 bar at 1.500 m3/h |

| Size: | 1 * 20 foot containers. |

| Weight: | 10.000 kg each container. |

| Power supply: | Deutz V6 Gen.set - 315 Kva, 50 Hz, 400V. |

| Connection to pipeline: | 2 x 6''ns flex hoses. |

| Building year: | 2014 |

| Environment: | No environmental disposal. |

To show the efficiency of the drying system, a comparison has been set up between a conventional drying spread consisting of desiccant units with compressors and the PS Pipeline Air Drying unit.

PS Pipeline Air Drying Unit: |

Conventional Drying Spread: |

||||

Produce 1.2 times more air

|

|||||

20% less drying time

|

4.5 times less fuel consumption pr. Hour

|

||||||

50% less equipment to transport

|

3 times faster to setup and connect

|

Other considerable advantages when using the PS Pipeline Air Drying unit:

- High volume minimize the risk of a foam pig being stocked in the line, due to air is bypassing

- Better cleaning of the pipeline due to higher velocity

- Lower pressure in hoses and fittings (max 1 bar)

- Equipment is easy to handle and transport as it is build in standard containers

- Less personnel to operate the equipment

- 100% oil free air is injected in the pipeline or piping system

- Less area is required to setup the equipment (only 1 x 20 foot containers)

- Less exhaust emissions due to less fuel consumption

- Less on-site oil change and service is required, normally a section can be dried within the service interval of the engines and no shot down in required at all.

- Less transport and storage of fuel is required on site.

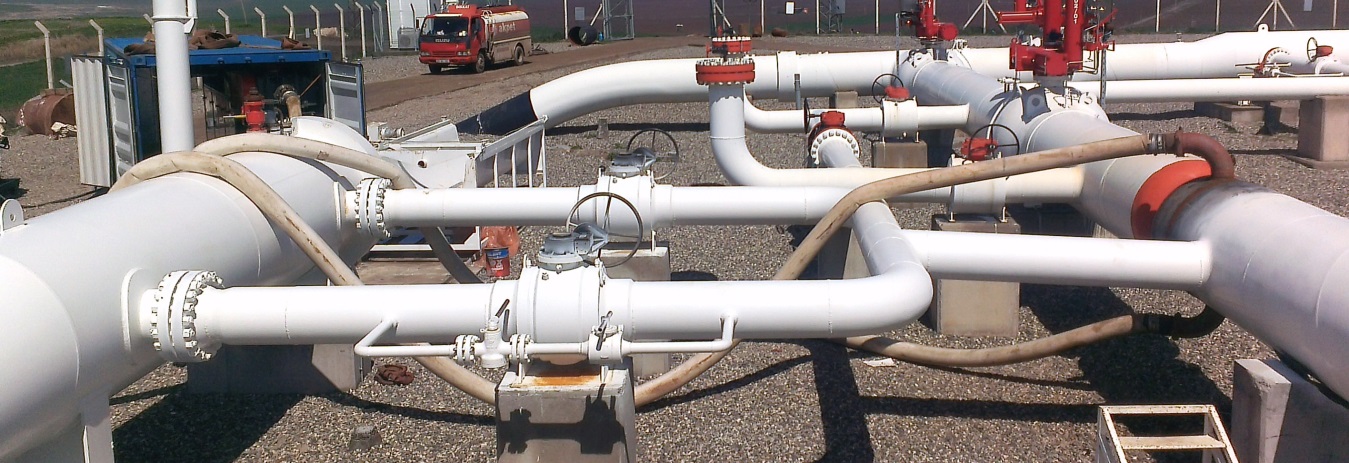

General Pictures of Drying Operation